Discover the Technology of 3D Printing

Over the 18th and 19th centuries the Industrial Revolution took manufacturing out of the hands of the common man and into the factories. The 3D printer has the potential to reverse this. The automated production of intricately shaped objects from a 3D computer design isn’t new.

Discover the technology behind the 21st-century industrial revolution being printed layer by layer…

Computerised numerical control (CNC) milling machines have been around since the Fifties. But CNC works by cutting material away from a solid block and there are lots of shapes that are physically impossible to make in this way. Imagine trying to make a hollow sphere, for example; unless the cutting tool can reach the inside, there’s no way to do it. 3D printing works in reverse: you start with nothing and progressively add material in layers to build up the shape you want. This places far fewer restrictions on the design.

Depending on the 3D-printing technique, it is possible to build intricate honeycomb structures that save weight without sacrifi cing strength and even objects that have moving parts – such as a working gear train – all printed in a single pass, with no need for assembly afterward. The 3D printer has been compared to the printing press, but, in fact, it’s a good deal more revolutionary than that. The printing press brought reading to the masses but it wasn’t until the word processor and the dot-matrix printer that ordinary people could actually write words of their own in any quantity. Now 3D printers are poised to democratise manufacturing. This isn’t just about copying existing factory-produced objects. For the fi rst time in history, we all have the power to physically create and manufacture just about anything we can imagine ourselves.

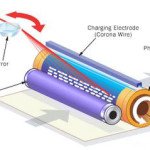

3D printing is also called additive manufacturing because it works by adding new material in layers. There are several different techniques, depending on the material you want to build from. The earliest system, called stereolithography, was invented in 1986 by Charles Hull. He used a special resin that hardens on exposure to ultraviolet light. By scanning a beam of UV light over the surface of a bath of the resin, he could create a thin layer of plastic.

The floor of the bath was then lowered slightly to sink the completed layer below the surface of the liquid resin and the light beam made another sweep. Each layer was bonded to the one below and eventually the completed object emerged. Stereolithography is still in use but if you want to build from metal, you need a different system. Instead of a bath of liquid, you shake a thin layer of metal powder onto the floor of the printer and use a high-power laser or electron beam to liquefy certain areas. The powder melts and fuses, you shake a new layer of powder on top and repeat. Because the object is always surrounded by a deepening bed of metal powder, you don’t need special struts to support the object as it builds.

For decorative figurines, powder bed printers can even create objects in full colour. These use a plaster powder and a printer that combines ink and a glue binder. At figureprints.com you can have your character from the online roleplaying game World Of Warcraft printed out in this way as your own full-colour memento.